Contact Us

CiiS Lab

Johns Hopkins University

112 Hackerman Hall

3400 N. Charles Street

Baltimore, MD 21218

Directions

Lab Director

Russell Taylor

127 Hackerman Hall

rht@jhu.edu

Last updated: 9:00 PM 3/9/15

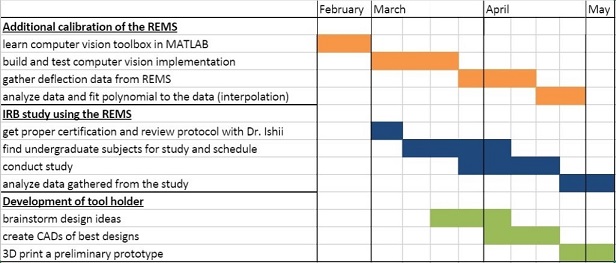

Our mission is to attack three distinct sub-projects relating to the Robotic ENT Microsurgery System developed by our mentors Kevin Olds, Russell Taylor, et al.

A paragraph or so here. Give background of the problem. Explicitly state specific aims (numbered list is good) and explain why they are important

We will briefly describe our technical approach to attacking our goals:

Extensive discussions and experimental practice will take place among the students, Kevin Olds, Dr. Taylor, and the surgical study team in order to ensure that the proper study protocol is taking place. An IRB-approved study will then be carried out in which experts and novices will identify anatomical targets using a tracked instrument in the cadaver sinus areas with and without robotic assistance. Undergraduates, preferably with proper certification, will be recruited by the student group for the novice section of the study. After all data has been collected, statistical analysis such as ANOVA will be used to validate the efficacy of REMS in sinus surgery.

The tool holder of the robot does not have perfect stiffness. This leads to a small error in the position of the tool tip when the robot is used admittance style. In order to account and calibrate for this error, we will use a computer vision approach to track the tool tip when a force is applied to the tool. An AX=XB calibration will be used to register the computer vision coordinates to the robots. The tooltip will be deflected with multiple forces at multiple poses of the robot. The force data will be correlated with the motion of the tooltip which will be tracked optically.

The current tool holder allows for free rotation of the tool. This is not a problem tracking when it comes to tracking a straight tool. However, many tools used by surgeons have angled tips. This creates a tracking problem as the robot currently cannot track the tip accurately given rotation of the tool is not tracked. To solve this, we will create a modified tool holder that will either guide rotation of the tool through a motor or track rotation through a sensor. Additionally, the tool holder must leave a small footprint as to not impair hand movement of the surgeon.

describe dependencies and effect on milestones and deliverables if not met

* Dependency name and short description

* Kevin Old's Thesis Draft

Here give list of other project files (e.g., source code) associated with the project. If these are online give a link to an appropriate external repository or to uploaded media files under this name space.