Contact Us

CiiS Lab

Johns Hopkins University

112 Hackerman Hall

3400 N. Charles Street

Baltimore, MD 21218

Directions

Lab Director

Russell Taylor

127 Hackerman Hall

rht@jhu.edu

Last updated: 05/08/2019

<html><span style=“color:red;font-size:150%;”>Statement of Confidentiality:</span></html> This website includes information, designs, and plans for items that have not been publicly disclosed due to intention of pursuing intellectual property. This site and its associated content, before that public disclosure, is only for the eyes of those who have signed a non-disclosure agreement.

We aim to deliver a functioning mosquito dissection system and demonstrate that it can autonomously process staged mosquitoes, removing and collecting their salivary glands. This dissection system will be designed to integrate as a component to a larger sporozoite-harvesting automation system under development by a larger team within the LCSR, that will be used to assist in the manufacture of malaria vaccines by Sanaria Inc. We intend to demonstrate the performance of our subsystem by the end of the semester.

Students: Henry Phalen, Michael Pozin, Alexander Cohen

Mentor(s): Dr. Russell Taylor, Dr. Iulian Iordachita

A group within the Laboratory for Computational Sensing and Robotics (LCSR) at Johns Hopkins University has been working on a project in collaboration with a local company, Sanaria Inc. Sanaria has developed a method to create a malaria vaccine, something that has a tremendous potential to impact global health. Some 500,000 people die from the disease annually that infects some 200 million per year. All told this is estimated to cost the continent of Africa alone some $12 billion USD in GDP loss (WHO 2018 World Report).

This vaccine requires the injection of radiation-attenuated sporozoites of Plasmodium falciparum (Pf), a parasite that causes malaria. These parasites are grown in mosquitoes which are then killed and dissected to extract their salivary glands where the parasite sporozoites are highly concentrated. At this time, technicians will manually dissect the mosquitoes under microscope with a small needle, removing the mosquito’s head, and expertly squeezing the body so that the salivary gland is pushed out and can be collected. This process is difficult to train and time-consuming, making it not feasible to produce vaccines at scale using this method.

A group in the LCSR demonstrated improvements in a mechanical-only dissection apparatus, and we will be working with a larger team to extend the knowledge learned in that endeavor to make the system automated. Our specific project aims are listed below:

Aims:

– New Deliverables –

Our new minimum deliverable was achieved. The goal was to develop a report and videos of the picking and placing of 50 mosquitoes using an integrated vision system without dissection of the mosquitoes.

Our new ideal deliverable is more on track. It has two parts; the first is a video of a processed mosquito from presentation to squeezing out of the glands, the second is a written report of design concept of our rotary stage. The goal of the first objective is to successfully process 50 mosquitoes from the presentation stage to the squeeze stage of dissection. The goal of our second is to have a first version finalized design of a rotary stage ready to be prototyped.

Our new maximum deliverable builds on our ideal. With the first objective being expanded to include Gland collection (which we see as a significant hurtle) and to be tested with 100+ mosquitoes. For the rotary stage we plan on having a first version physical prototype with integrated subsystems for dissection though without pick and place using a robot since it is likely a different robot will need to be developed for this new design.

– Prior Deliverables –

Our minimum requirement concerns the development and improvement of an existing setup that has previously been worked on by members on this team. The system as it currently exists has several incomplete or undeveloped subsystems. To achieve this goal we are focused on getting the squeeze mechanism, gland collection device, and body disposal subsystems designed, implemented and tested.

Our ideal goal is threefold; written report detailing the system integration (w/o vision), automated dissection of 50+ mosquitoes, and a written report of the design of a new rotary stage concept. The written report detailing the system integration without vision, will require us to have developed the system to a point where it is processing mosquitoes. For this report we’d expect our system to be up an running to the point where it is capable of automated dissection of a minimum of 50 mosquitoes. This will give us a good idea of the viability of the system as well as shed light on any issues we find with the subsystems and will show how well the system integrates into the larger system. The report will include the results of our testing, a detailed account of the design of the system, how our system was tested, taking the form of something similar to the methods section of a standard research paper. Currently we are mainly focused on a linear stage design which has obvious downsides as compared to a rotary system when it comes to continuous dissection of mosquitoes. We plan to have developed a clear design concept of a rotary stage design which implements the subsystems for the current design with likely some small modifications.

Our maximum deliverable is similar to the ideal except it required us to have completed a written report detailing the system integration with vision, the automated dissection of 100+ mosquitoes, and a physical prototype of the rotary stage.

1. Changes to Pick-and-Place System We first intend to make minor changes to the robotic pick-and-place assembly such that the system is both able to better accommodate mosquitoes during processing. In order to achieve a desirable accuracy, we will be implementing a number of small mechanical designs to the stage on which the mosquitoes are handled, specifically hoping to reduce collisions of the mosquito body with other parts of the apparatus while the head is being placed between the blades. Additionally we intend to implement computer vision aspects of mosquito detection to provide mosquito-specific movements.

Robot path is shown when using the segmentation computer vision algorithm and the manual dissection system (sAMMS). This method uses an on-board camera that has to get close to the mosquito to get a good image, hence the ‘b’ action in the figure.

At left the segmentation computer vision algorithm, at right an example of the keypoint computer vision algorithm output with the keypoints labeled. These are the computer vision algorithms developed by our collaborators Prasad Vagdargi and Hongtao Wu respectively. We used these vision algorithms to guide our robot.

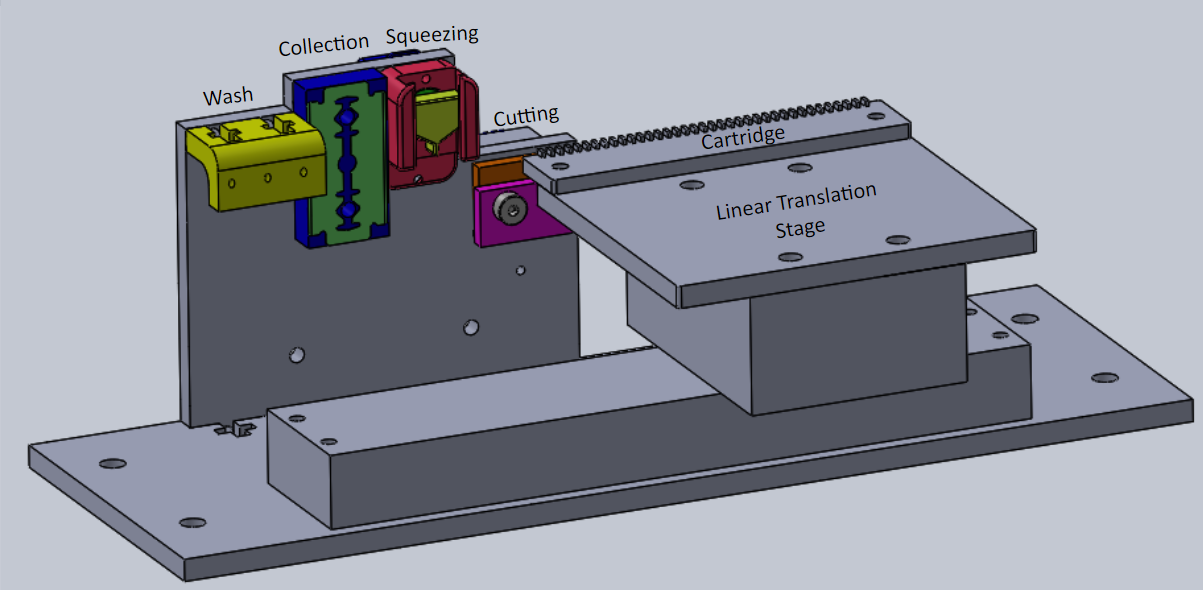

Short and most current dissection apparatus (left) and longer version of the dissection apparatus (right). Difference between the two assemblies is that the longer version contains that body disposal component which is outlined in red. Both accommodate a mock staging component but this is not shown on the longer version.

2. Developments and Improvements of downstream dissection

We intend to further develop the current dissection system such that it is capable of processing mosquitoes from placement into cartridge to gland collection. The steps required in the dissection process include: (1) decapitation, (2) squeezing, (3) gland collection, and (4) body disposal and cartridge cleanse. We intend to continue developing existing processes such that an integrated multi-functional can be produced and then to rigorously test the systems at unit scale and as a whole.

Original linear stage design at start of project.

Robotic system used in this project. Included in this figure is the manual dissection apparatus used in early tests.

3. Multi-system integration We intend on developing a single high-level control package such that a single systemic timing bottleneck (likely to be robot motion) will become the only bottleneck in our system. We intend to facilitate multiple system level actuation units simultaneously by means of a single high-level control system which ought to communicate with several different low-level control systems. This presents a significant challenge as the different subsystems controllers operate at different frequencies and have been developed in different languages. We anticipate that our finalized system will integrate all of the components developed by our team as well as those that become sufficiently developed by our collaborators.

Block diagram of software architecture and the interfaces with hardware

4. Rotary Stage Design We plan on integrating a rotary stage design for cartridge motion within the dissection system. This will enable the system to function continuously in contrast to the developed linear system (which requires a “reset” motion of about 12 seconds, once every 36 mosquitoes processed) and reduce the dissection system bottleneck to just over a one second time during operation. Developing this rotary system will improve overall system efficiency and will utilize many of the existing components from the current linear dissection system.

Concept concentric rotary stage design

Rough design of the three subsystem around the tangential rotary stage. Front view (left), Isometric view (middle), and top view (right). Rotation of stage is clockwise as viewed from the top view.

Possible mating of tangential rotary stage with existing feeder stage. This is just a suggested setup with the idea that the overhanging robot would not need to rotate after picking up the mosquito to place it but other configuration are possible where the cups are closer to the cutting mechanism. Isometric view (top right), top view (top left) and side view (bottom). Looking at the side view the feeder will need to be on a elevated stand but this is not seen as a significant problem which is simple to solve.

UPDATE 1: Rotary Design Change

The original stage in the system above was not sufficiently supported for a proper rotary stage design so a simple support system with bearing surfaces was designed. There is a three legged table like design with a standard roller-ball bearing for axial alignment and a thrust bearing for smoothly supporting the rotary stage on the table, also it should be noted that the feeder was moved closer to the cutter to minimize the travel distance of the mosquito.

Front section (left) and isometric view (right) of design additions to the rotary stage.

UPDATE 2: Rotary Design Change

There was a significant oversight in the design of the rotary stage the designed was overhauled to accommodate this. (Details on this change can be found in our report and presentations section in the document titled: Design Report of Rotary Stage (Final Revision))

Rotary table design revision to accommodate mosquito dragging, two isometric views of the inverted rotary stage design highlighting different key features.

Rough idea of robot position relative to the system. Highlighted in red is the relative workspace of robot gripper end effector.

<fs larger>– Mechanical Design –</fs>

Current Gripper Design

Custom-designed micro-gripper used to grasp mosquitoes. Inset is a close-up view of the micro-gripper and sleeve parts taken from the Alcon tool.

Possible New Gripper Design

The above two figures show a first version design for a new gripper for the robot stage. It utilizes a linear actuator instead of the current standard rotational servo motor cam design.

Decapitation Mechanism:

Labelled front (top left) and top (top right) schematics of the dissection apparatus. Workflow and operation visualization of the cutting component on the bottom showing the substrates in their passive positions on the left and right and the actuation motion of the moving blade in the middle.

Squeezing Mechanism

Key components of the squeeze/collect apparatus in front view (top left) and top view (top right). The three motion compoents are shown on the bottom with the assembly passive on the left, the pressing motion depicted in the middle, and the collection microdissection step shown on the right.

Useful References:

Reading List:

Code is housed in a private GitHub repo. For confidentiality, please contact henry.phalen@jhu.edu for access.

All other documents are housed in a JH Box folder for the larger LCSR project. Again, for confidentiality there are concerns with posting any outward facing links. Contact henry.phalen@jhu.edu for access to documentation.